In recent years, the invention of turbochargers has paved the car owners’ way to their horsepower by using air that would otherwise be wasted in the exhaust. It’s done by channeling the gases back into the engine for more power. Because turbochargers are an essential component in most modern combustion engines when they fail, it means the engine may fail, too, so it’s vital to keep the turbo working at peak levels.

In this guide, we will delve into the leading causes of turbo failure and how you can avoid them. First, how can you determine that your turbo is failing?

Turbo failure symptoms

Here are various signs that will tell you if your turbocharger is blown.

Loss of power

If you note that your vehicle isn’t accelerating as fast as it used to or is slow to react to any input, it means your turbochargers may fail. Similarly, if the vehicle is struggling to maintain high speeds and is struggling to reach speeds it once used to, you could be experiencing turbo failure.

If the engine is whining

One advantage of turbochargers is that they aren’t noisy. They make the engine quieter by muffling the air intake’s sound. However, if you notice a loud whining noise, a bit like an ambulance siren, or a dentist’s drill, it could mean there’s trouble with your turbocharger. If the fault gets more serious, the noise will get worse. Whenever there’s any noise coming from your engine, you should have it checked by a professional mechanic.

Smoke from your exhaust

When there’s an oil leak and flows into the exhaust system, there will be a noticeable blue or grey smoke as it burns off. The oil leak could be originating from a crack in the turbo system or damaged internal seals. If the turbocharger causes this symptom, you’ll see the smoke as the engine revs increase shortly after idling.

Check if the engine light is on.

Most modern automatic cars come equipped with computer diagnostics. When there’s an issue with the engine, and possibly the turbocharger, the engine light will be turned on the dashboard to notify you that there’s a problem.

What causes turbo failure?

Oil

Less than 1% of turbochargers fail due to manufacturing problems, while more than 90% of turbo failures are related to oil, either oil starvation or oil contamination.

Engine oil is vital in any vehicle, and when it comes to the turbocharger, the engine oil works to maintain optimum functionality of the main shaft assembly. The assembly is where the turbo compressor and turbine wheels are mounted. The oil lubricates all the moving parts to protect them from corrosion and ensure they are cool.

The turbocharger requires a constant flow of quality, clean oil. Lack of oil, also known as oil starvation, poor-quality oil, or low-grade oil, will also lead to the buildup of contaminants in the engine, which causes oil contamination. This will cause abrasive damage to the inside of the turbocharger. You must change the engine oil as recommended by the manufacturer. If not, then it will lead to insufficient oil and oil starvation.

Restricted or a broken oil feed pipe can also lead to a lack of lubrication. If your turbocharger has been refitted without proper priming, it will lack sufficient lubrication. If the lubrication system has malfunctioned and there’s low pressure that can’t circulate the oil properly, it may cause problems. If the oil is leaking, it may also mean your fuel injection pumps aren’t being lubricated and may cause it to stop working, which prevents fuel from flowing to the engine.

Some of these issues can be repaired using the right grade oil, as well as changing your oil and filters frequently. You could also try to warm up the engine, especially during the cold season, to allow the oil time to circulate and lubricate the intricate parts of your engine and turbocharger. After driving, you should enable the engine to cool down to avoid the turbo’s heat from cooking the oil, which may cause carbon buildup and eventually lead to bearing failure. Sometimes, you may need to change your injection pump, and you can do this at https://goldfarbinc.com/collections/bosch-injection-pump.

Foreign objects or deposits

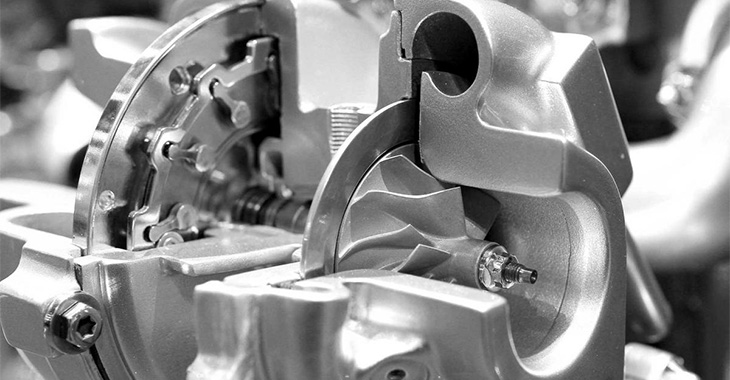

A turbocharger is typically made up of two main components – the compressor at the front and the turbine at the back. Foreign objects such as dust particles, leaves, dirt, or small stones can enter the turbo either via the turbine or via the compressor inlet. The foreign particles that enter the compressor housing come from the air filter, and if the foreign object damages your turbine, then the problem may have originated from the engine.

The turbocharger will stop running efficiently if foreign objects start damaging the compressor wheels or turbine blades. To avoid this, you should change your air filter regularly. You should also have your turbo checked for any debris.

Damaged seals

If the seals between the engine and compressor are worn out or cracked, it will cause oil leakage into the exhaust system. As a result, the turbocharger will be working extra hard to increase air pressure. The problem is also known as overspeeding. This is when your turbocharger is working way above its normal levels. Ultimately, it will reduce the boost delivered by the turbo and its efficiency to perform well.

Ensure that you have your vehicle checked to repair or replace any damaged seals.

Conclusion

Turbochargers are manufactured to last the lifetime of the vehicle. However, they can wear out with time, depending on how you take care of your car and some driving habits. As soon as you spot any of the symptoms indicating your turbo may be failing, ensure that you have your vehicle checked. You can still drive your car with a failed turbo, but engine failure won’t be far behind, so only do it if necessary.